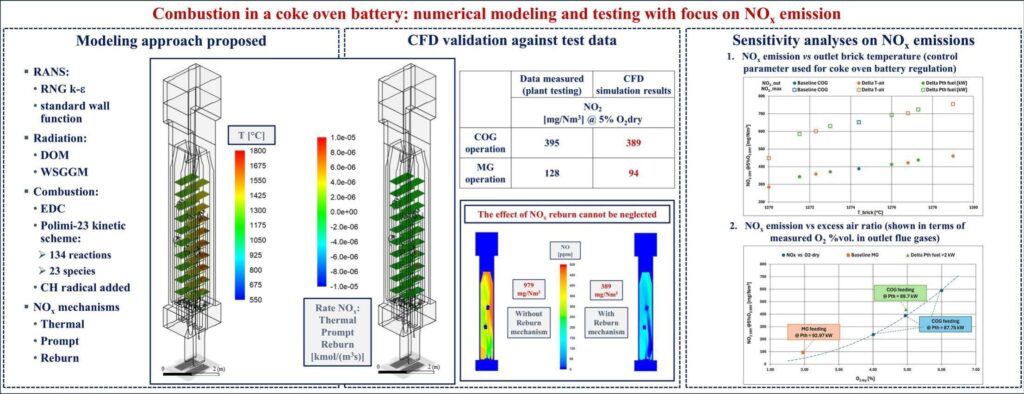

Termotecnica Industriale contributed to an article published in Thermal Science and Engineering Progress, in collaboration with Paul Wurth Italia (SMS group Italy) and their engineers, who are co-authors on the paper and whose technical expertise played a crucial role in advancing this research. The study focuses on advanced CFD modeling of combustion processes in coke oven batteries using steelmaking process fuels.

Key highlights of the research:

▪️ Innovative CFD modeling of combustion in a coke oven battery using process‑derived fuels

▪️ Advanced chemistry modeling with NOx evaluation via post‑processing

▪️ Experimental validation confirming the relevance of NOx reburn mechanisms

▪️ Sensitivity analyses on thermal input, air inlet temperature, and excess air ratio

▪️ A general, tuning‑free approach delivering accurate NOx predictions

At Termotecnica Industriale, R&D is at the heart of everything we do. Our R&D department, with the CFD and process simulation unit, is developing our new combustion technologies, as well as supporting our partners for their R&D activities, in the context of emission reduction and energy transition. We develop cutting-edge technologies for combustion and CFD and multi-physics simulations, employing state-of-the-art software tools.

Thank you to everyone involved and to our partners for the excellent collaboration!

👉🏼 Read the full article: https://www.sciencedirect.com/science/article/pii/S2451904925012260

#ResearchAndDevelopment #CFD #CFDModelling #Energy #NOx #CokeOvenBattery #Engineering #EnergySolutions #EmissionReduction #EnergyTransition #Combustion #TermotecnicaIndustriale #PaulWurthItalia